Well Point Dewatering System

Well point dewatering system. Disadvantages of Well Point System. This method works via the venturi principle. Well Point Dewatering System In excavation sites a simple yet efficient method of lowering the water table is using well point dewatering.

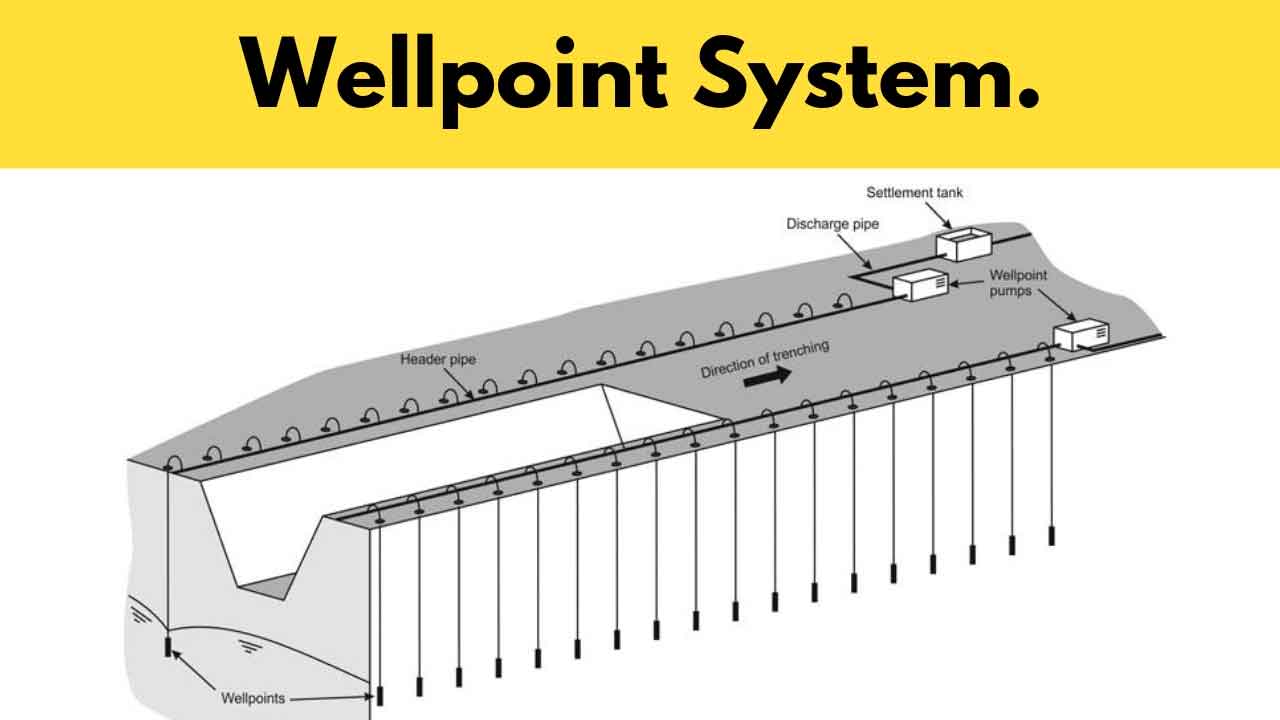

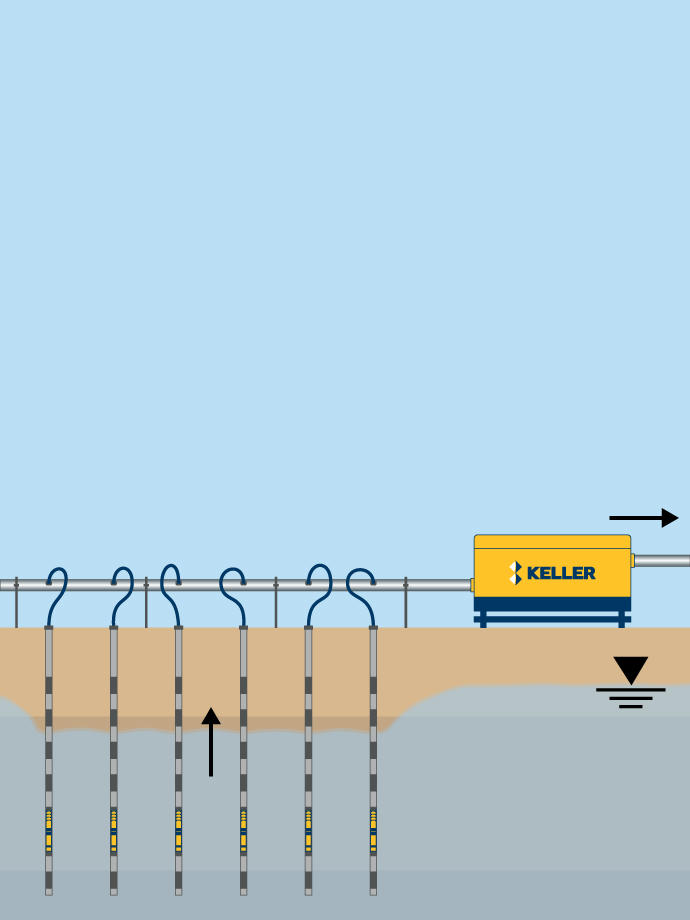

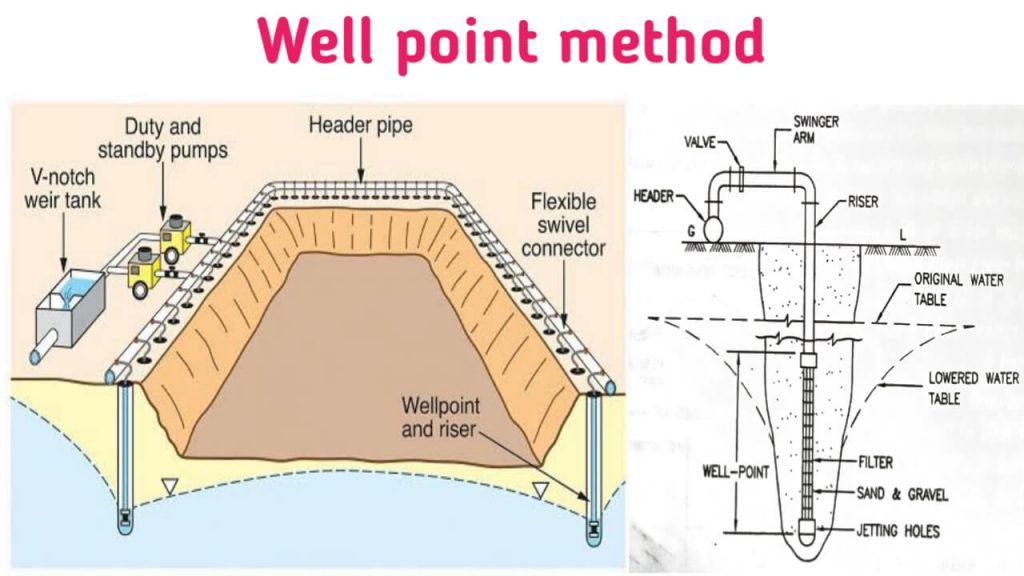

A wellpoint dewatering system consists of a series of shallow wells known as wellpoints which are installed at a pre-determined depth and appropriate spacing around an excavation. The flow to become turbulent. In well point system the water is generally lifted by difference between ambient air pressure and the lowered pressure created by the pump.

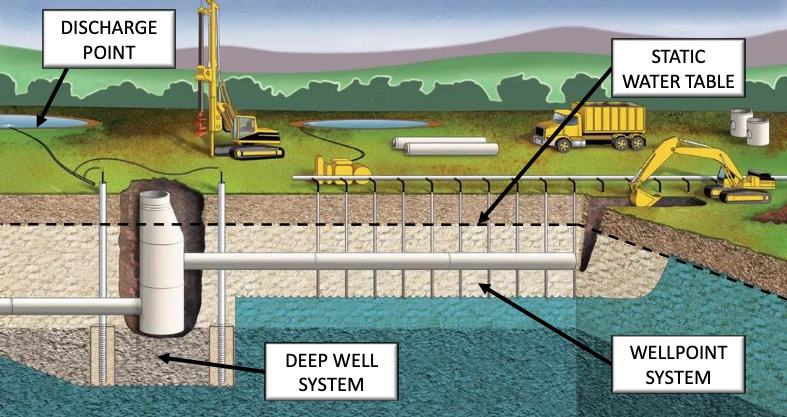

Wellpoint dewatering is a process where groundwater levels are lowered enough to create a stable working environment. In this case high-pressure water circulates through eductors in each well triggering a vacuum. Wellpoint systems are used to lower groundwater levels to provide stable working conditions.

Wellpoint systems are used to lower groundwater levels to provide stable working conditions. The educator well method is also an effective method. The pump creates a vacuum in the header pipe drawing water up from the ground.

Quantities of water from a single hole. Therefore the design of a dewatering system should always be checked to see that the well or wellpoints have adequate wetted screen length h ws or submergence to pass the maximum computed flow. Wellpoints are small-diameter about 40 - 50 mm tubes with slot.

This is a dewatering process which can control pore water pressures in materials with low permeability characteristics like slits or fissured clay. System Design The objectives of a dewatering system will depend on many factors and no two dewatering systems are the same. They consist of a series of small diameter wells that are connected by a header pipe to a wellpoint pump.

NCS Fluid Handling Systems has one of the largest privately owned and maintained fleets of well point dewatering support equipment in the region with over 25 speciality dewatering pumps 4 hydraulic drive auguring systems numerous water jet systems and a massive number of points and header located strategically across all 5 of our branch locations and on project sites across Canada. MWI wellpoint dewatering systems are specifically suited for removing water from unsettled or unstable ground including weak foundations and trenches.

Wellpoints are small-diameter about 40 - 50 mm tubes with slot.

In planning to install or use dewatering we consider many factors from soil conditions method of construction and the header elevation to water volume pump and discharge location etc. They consist of a series of small diameter wells that are connected by a header pipe to a wellpoint pump. This is a dewatering process which can control pore water pressures in materials with low permeability characteristics like slits or fissured clay. Malcolm has years of experience in dewatering projects throughout the United States and our complete design and installation services can help in even the most challenging underground conditions. A typical wellpoint dewatering system will consist of a number of calculated wellpoints which are installed at an effective depth and appropriate spacing around or parallel with the excavation. Disadvantages of Well Point System. Therefore the design of a dewatering system should always be checked to see that the well or wellpoints have adequate wetted screen length h ws or submergence to pass the maximum computed flow. Satyam Dewatering Systems is one of the leading Construction Dewatering companies in India. The Dallai Wellpoint system is the best solution to drain the ground for the construction.

NCS Fluid Handling Systems has one of the largest privately owned and maintained fleets of well point dewatering support equipment in the region with over 25 speciality dewatering pumps 4 hydraulic drive auguring systems numerous water jet systems and a massive number of points and header located strategically across all 5 of our branch locations and on project sites across Canada. In addition to lowering the groundwater. It is a pioneer in the arena of Well Point Dewatering System Open De-watering Deep Borewell Dewatering Systems. System Design The objectives of a dewatering system will depend on many factors and no two dewatering systems are the same. A typical wellpoint dewatering system will consist of a number of calculated wellpoints which are installed at an effective depth and appropriate spacing around or parallel with the excavation. Wellpoint Dewatering also known as Sandpoint Dewatering is a method used to stabilize soil. This is a dewatering process which can control pore water pressures in materials with low permeability characteristics like slits or fissured clay.

Post a Comment for "Well Point Dewatering System"